PRODUCCIÓN

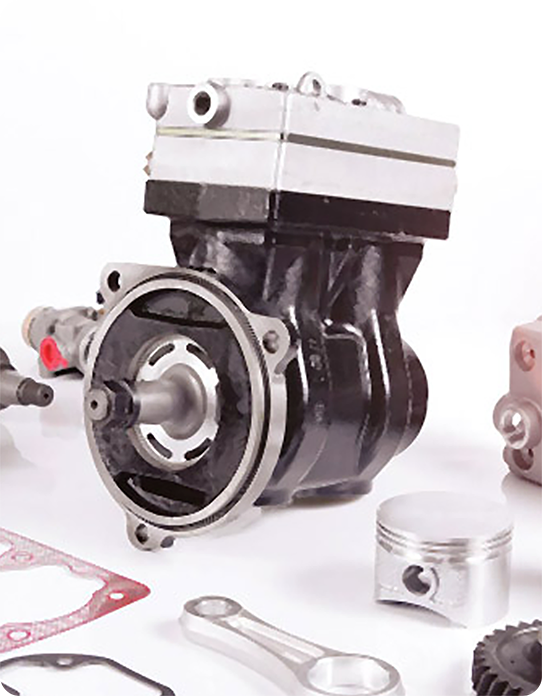

El poder del aluminio, la perfección de la fundición.

Nuestro departamento de I+D se encuentra en un número significativo de metros cuadrados de área cerrada, y planeamos expandir nuestras capacidades para apoyar mejor los proyectos en desarrollo.

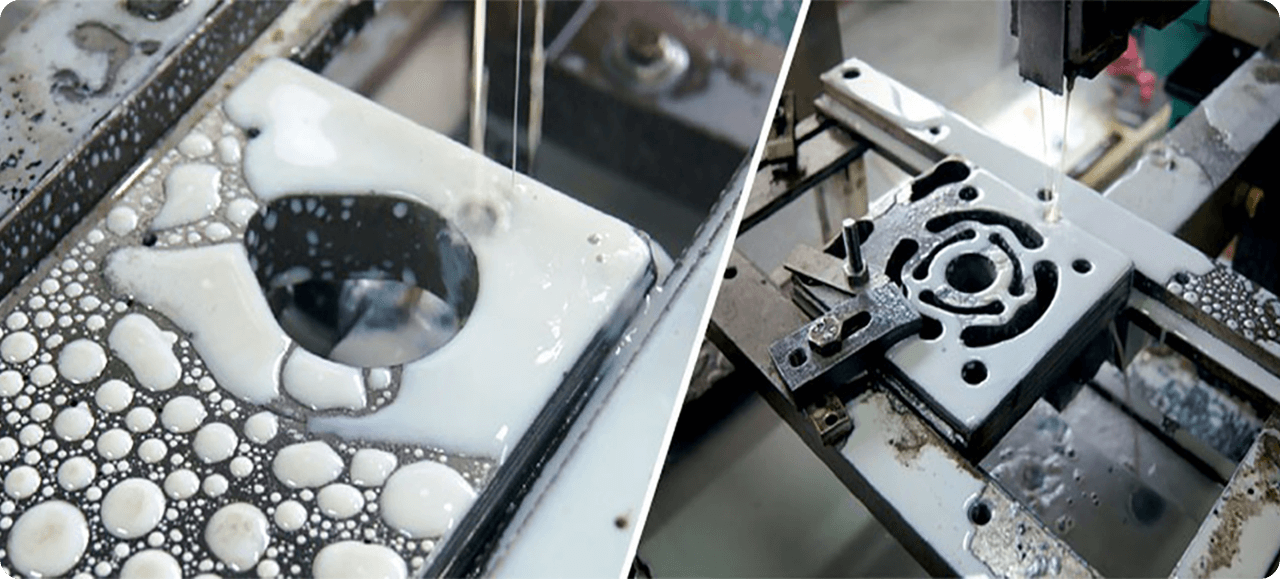

DIFERENTES MODELOS

El conocimiento y diseño añadido en nuestra empresa continúa evolucionando de su posición actual inadecuada hacia productos de mayor valor añadido.

GARANTIA DE CALIDAD

Los criterios de diseño de los productos con los que trabajamos se identifican y se manejan los procesos de desarrollo-verificación de productos apropiados dentro del marco de las normas pertinentes.

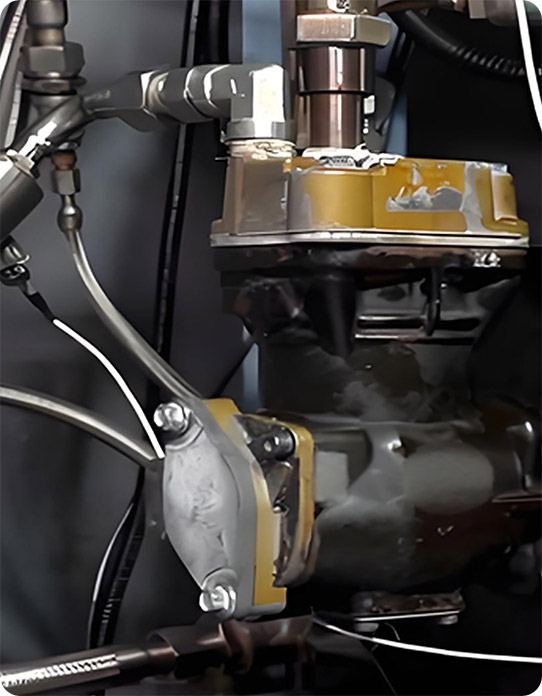

SERVICIO TOTAL

Nuestro objetivo es proporcionarle la mejor calidad a un precio competitivo, para todas sus necesidades de partes de frenos de aire y relacionados.

MODELOS DIFERENTES

El conocimiento y diseño de valor añadido en nuestra empresa continúa evolucionando de su posición actual inadecuada hacia productos de mayor valor añadido.

GARANTIA DE CALIDAD

Los criterios de diseño de los productos con los que trabajamos se identifican y se manejan procesos de desarrollo-verificación de productos apropiados dentro del marco de las normas pertinentes.

SERVICIO TOTAL

Nuestro objetivo es proporcionarle la mejor calidad a un precio competitivo, para todas sus necesidades de partes de frenos de aire y accesorios relacionados.

PRODUCT RESEARCH & DESIGN

Our R&D department is located on a significant number of square meters of closed area, and we plan to expand our capabilities to better support developing projects.

Our company, WBS Technology (Taizhou) Co. Ltd, boasts of an outstanding independent R&D department that was established in 2008 to produce our own products under the WBS brand. Our products are continuously reciprocating piston compression machines, and we design them with high mechanical precision, incorporating numerous components, functions and complete product validation.

To ensure we maintain our high standards, we have set up R&D infrastructure and numerous projects in our laboratory to perform metrology, metallography and dynamic-static tests. We recognize that our most important R&D resource is human potential, and therefore continue to recruit, train and develop qualified personnel for our team. We also maintain cooperation with universities, providing our team with new projects and continued support.

Our company has made significant investments in performance test devices and metallography devices that are our own designs and support prototype product design, testing and verification studies. Our departments use software simulation programs like CAXA software to ensure optimal product design.

We are currently negotiating with a number of OEMs, exploring potential projects and making improved investments in order to adapt to new requirements and developments in the market. We are confident in our testing process, both in the lab and on vehicles, conducted alongside dynamical and static experiments, with dimensional, metallographic, chemical and mechanical properties all tightly measured to ensure quality.

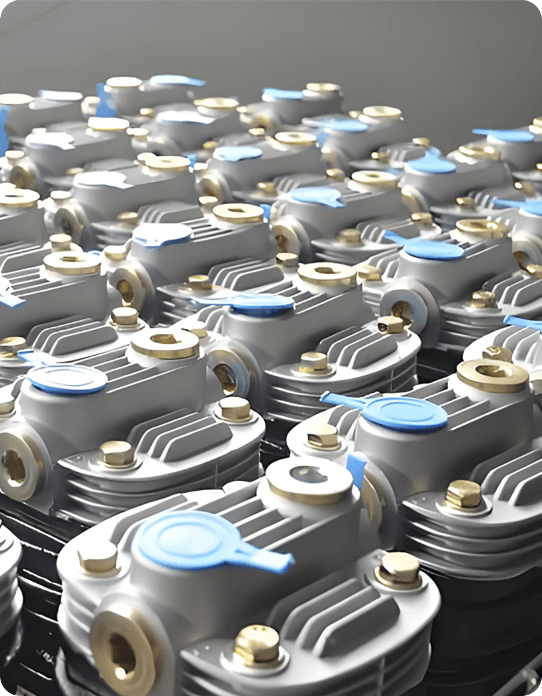

COMPRESSOR TESTING CENTER

Trust Weibaisen Technology to deliver compressors with unmatched performance and reliability.

At WBS, we conduct dynamic tests on our compressors in our state-of-the-art laboratory to ensure optimal performance under real-world conditions. Our testing process collects thousands of samples each minute, per channel, giving us precise and reliable data on the performance parameters of our products. Our custom-designed dynamic testing device, developed in collaboration with a top university, is equipped with dozens of sensor channels, providing instantaneous, cumulative, and fatigue performance criteria control for the compressors. As we continue to innovate and expand, we plan to incorporate two additional test devices, including one with a climatic chamber, into our upcoming projects. Trust Weibaisen Technology to deliver compressors with unmatched performance and reliability.conducted alongside dynamical and static experiments, with dimensional, metallographic, chemical and mechanical properties all tightly measured to ensure quality.

ENGINEERING

Reverse engineering, product modeling, analysis, fixture design and control processes are carried out studiously by expert personnel in our engineering department.

The Method Department performs the designing and manufacturing of the fixture-apparatus in order to produce real processes in accordance with quality standardization in developed and finalized products.

PACKING LINE

ASSEMBLY LINE

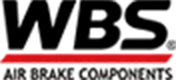

MACHINING LINE

Our company sustains the manufacturing of the products that are exported to all over the world, with punctiliously chosen, sensitive & high performance CNC workbenches.

In our production department, there are 26 CNC horizontal & Vertical machining centers, 5 multiaxial sliding automats, 16 CNC lathes, 54 machines in total including CNC Honing Machine. The manufacturing with suitable workbenches for modern hydrolic fixtures and high cutoff regimes develops with the unity of man power and advanced technology in each production process. Like always, we focused on the minimum fail, maximum quality principle.

MOULD

Mould manufacturing processes are handled by expert personnel in the related department.

Mould manufacturing is a procedure that consists of the moulding processes of the products that are professionally designed by the qualified R&D personnel; and also it’s assisted by simulation software for casting products and the AutoForm for sheet materials.

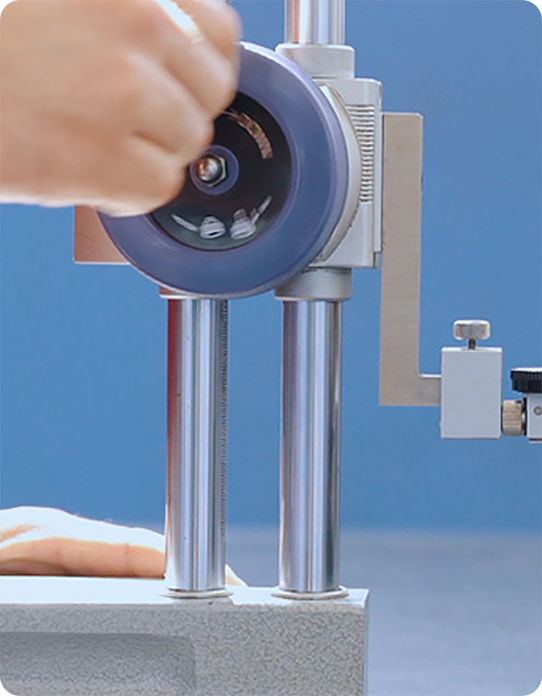

METALLOGRAPHY LABORATORY

Materials are characterized with micro structure investigation. Material properties and performance depends on microstructure, and microstructure formed with production parameters.

The parts can be analyzed whether suitable for operational condition or not with microstructure characterization. Below list is showing our capabilities in our lab;

– Chemical analysis,

– The grain size of the material,

– The history of the material (what kind of processes it was exposed to before),

– What kind of operation can be applied,

– Microstructure,

– Residue (inclusion) type, pattern, density,

– Segregation status,

– Crack,

– Depth of hardening,

– Nitration,

– Coating thickness,

– Gas gaps,

– Casting cavities,

– Graphite type and pattern.

Descubre por qué somos tu mejor opción

Nuestro objetivo es proporcionarle la mejor calidad a un precio competitivo, para todas sus necesidades de partes de frenos de aire y relacionados.

Exportar a más de 110 países

trae calidad y confianza a cada

rincón del mundo

En línea 24/7

para apoyarte en cualquier momento

Más de 150 expertos

servir y dar la bienvenida a nuestros

clientes

Exportar a más de 110 países

trae calidad y confianza a cada

rincón del mundo

En línea 24/7

para apoyarle en cualquier momento

Más de 150 expertos

servir y dar la bienvenida a nuestros

clientes

Soporte al Cliente

Contamos con un equipo de soporte al cliente dedicado y experto que está encantado de proporcionar cualquier ayuda que sea necesaria

Seguridad en línea

Proporcionamos un proceso de pago seguro y protegemos cuidadosamente su información personal

Envío

Enviamos pedidos mediante contenedores completos (FCL), lote de contenedores (LCL), UPS, FedEx, DHL Express todos los días y nos enorgullecemos de procesar pedidos rápida y eficientemente

Soporte al Cliente

Contamos con un equipo de soporte al cliente dedicado y experto que está encantado de proporcionar cualquier ayuda que sea necesaria

Seguridad en línea

Proporcionamos un proceso de pago seguro y protegemos cuidadosamente su información personal

Envío

Enviamos pedidos a través de contenedores FCL, LCL, UPS, FedEx, DHL Express todos los días y nos enorgullecemos de procesar pedidos rápida y eficientemente